‘The Rare Earth’ is publishing exclusive material about the developments in the sphere of beryllium. These developments from the A.A. Bochvar High-Technology Scientific Research Institute for Inorganic Materials (JSC VNIINM) allow the creation of hi-tech products with a wide range of applications.

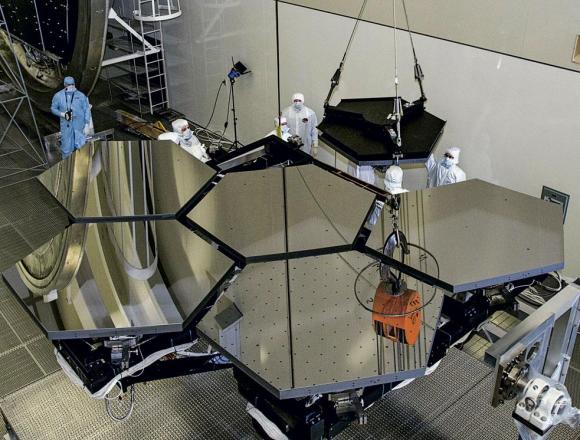

Beryllium combines lightness, strength, high elastic modulus, high X-ray transparency, chemical resistance and the ability to operate at elevated temperatures, which provides its scope of application. As an alloying element, beryllium is able to literally transform base metals. Thus, beryllium bronze has some characteristics that are superior to alloy steel, making this bronze indispensable for contact devices and springs plus specialized tools. Since the 1950s, JSC VNIINM has taken an active part in the technological development of beryllium and the manufacture of products, accumulating great experience in this area. In recent decades a series of new promising applications for beryllium has appeared. One of those applications is the use of beryllium oxide as an additive to the formation of uranium dioxide fuel pellets for nuclear reactors, because it significantly increases the thermal conductivity of nuclear fuel and contributes to its high degrees of burnout. The Russian grade of beryllium TGP — 56PS, created by JSC VNIINM, received permission from the ‘International Thermonuclear Experimental Reactor organization’ (ITER) to be used as a coating for the first wall of a fusion reactor built by VNIINM. Together with the Federal State Unitary Enterprise ‘Troitsky Institute for Innovation and Fusion Research’ VNIINM launched the world’s first quasi-stationary plasma accelerator for work with beryllium materials. VNIINM uses its industrial site for these purposes and at the present time it conducts all sorts of experiments in conjunction with different varieties of beryllium with plasma in conditions as close to the working conditions of ITER. JSC VNIINM created an experimental site for the production of vacuum-tight beryllium foils used for x-ray equipment, and created a whole range of technologies for their production. VNIIM manufactured several experimental batches of beryllium foils with a thickness of 8 to 300 microns, carving out X-ray windows in them (a diameter of 10 to 30 mm) and achieving a high purity of beryllium, in terms of radiopaque tinctures. (<500 ppm, in particular, iron, <100 ppm). JSC VNIINMalso developed a technology based on nanocrystalline beryllium for the production of metal with one hundred percent open porosity (so-called ‘penoberilly’) and with great potential as a structural material for open space installations. Its density is 5 times less than that of water and can be used for the manufacture of load-bearing structures where each extra gram counts. Furthermore, using ‘penoberilliy’, VNIINM can make cosmic mirrors with high albedo (reflection factor) in the infrared spectrum. Beryllium oxide ceramic is a dielectric with abnormally high thermal conductivity — greater than that of some metals. It is exceptionally heat resistant and will not crack under harsh temperature changes. These properties allow the creation of large power microchips based on beryllium oxide substrates which are indispensible for installations operating in open space. The same substrates are used for the production of traveling-wave tubes — essential for radars, radio stations and other transmission systems.